Thermochemical Hydrogen Production

Four-Step Copper-Chlorine (Cu-Cl) Cycle

The threats of climate change and depletion of conventional fuels are driving the demand for clean energy. Hydrogen has the potential to fill much of this demand. However, hydrogen is a paradoxical fuel: it is clean to use, but generally dirty and polluting to produce. About 97 per cent of today’s hydrogen is derived from hydrocarbons such as natural gas and coal. Our research will develop cleaner methods of hydrogen production through an emerging new water-splitting technology called the copper-chlorine (Cu-Cl) cycle. This cycle will eliminate greenhouse gases and other air pollution generated by existing carbon-based methods of hydrogen production. The results of our research program will make hydrogen as “green” to produce as it is to use, and put Ontario at the forefront of clean hydrogen technology.

Our research aims to develop and successfully demonstrate the world’s first integrated Cu-Cl cycle of clean hydrogen production. Our ORF-RE “Phase I” grant, awarded in 2006, has allowed our team to complete each of the four main unit operations of the Cu-Cl cycle. In this proposed “Phase II” continuation of our research program, our team intends to link these unit operations, supply products from one operation as reactants to the next process, remove and recycle byproducts, and thus demonstrate a fully integrated cycle by 2016 that produces about five kilograms of hydrogen per day, continuously, over a period of several weeks. Beyond this stage, companies would license the technologies, thereby enabling industries to build their own plants at scales to fit their own particular needs. This project features a significant level of industrial collaboration, including major cash investments as well as 15 industry personnel from six Ontario companies that aim to license the proprietary technology into their specific domains. It also includes significant leveraging of their resources towards the project, including time spent by personnel, and facilities developed at partner sites.

Our research program will apply fundamental scientific knowledge – generated from targeted basic research in thermochemistry, electrochemistry and materials science – to systems incorporated by engineers into the integrated Cu-Cl cycle. Several technologies necessary for the successful deployment of the cycle are included, such as:

- corrosion-resistant materials

- electrical, control and safety systems

- electrochemistry required for membrane scale-up

- thermo-chemistry database for Cu-Cl compounds

(Membrane scale-up refers to technologies that improve the durability, lifespan and performance of electrode materials.)

Initially, only Canada and the U.S. were developing the Cu-Cl cycle, but given the setbacks in other thermochemical cycles and major recent breakthroughs by our team, other countries, such as France, South Africa, Romania, India and the EU, have been able to establish their own Cu-Cl programs. Following on our ORF-RE “Phase I” success, our primary goal now is to lead the world’s first integrated Cu-Cl demonstration plant. This would position Ontario on the world stage with global leadership of the Cu-Cl cycle for clean hydrogen production.

Hydrolysis Facility at CERL

Membraneless Three-Step Copper-Chlorine (Cu-Cl) Cycle

Thermochemical cycles consist of a series of chemical/electrochemical reactions that occur within the cycle, and water is decomposed into hydrogen and oxygen in different reaction steps in the cycle. The cycle is completed by using different copper compounds in each reaction step in Cu-Cl cycles. Each of the reaction steps takes place at a specific temperature. The Cu-Cl thermochemical water-splitting cycle is a promising technique for large-scale hydrogen production. The systems in which both heat and electricity are provided within the cycle are called hybrid thermochemical cycles. Systems that do not require electricity and provide only heat for all reactions to occur are called pure thermochemical cycles. The relatively low-grade temperature requirement for the cycle is an important advantage. Due to the low temperature requirement, the heat required in the cycle can also be supplied from waste heat from facilities, solar thermal plants, geothermal and nuclear energy.

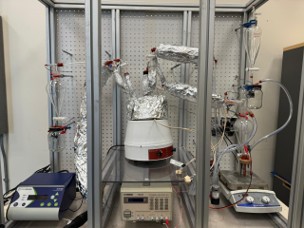

Experimental Setup of Membraneless Cu-Cl Cycle in the CERL

Mg-Cl Cycle for Hydrogen Production

Our experimental setup for the Magnesium-Chlorine (Mg-Cl) cycle is designed to efficiently produce hydrogen through thermochemical water splitting. The system includes a high-temperature reactor for MgO chlorination, an electrochemical cell for hydrogen and chlorine gas separation, and a thermal decomposition unit for HCl recycling. Precise temperature control, gas flow regulation, and real-time monitoring ensure optimal reaction conditions. This research aims to enhance efficiency, scalability, and sustainability in clean hydrogen production.

Experimental Setup of Mg-Cl Cycle in the CERL